İnsan sağlığına etkileri

Fog particles It is so small that it can easily travel through the body, penetrating the lungs, mucous membranes, and even the bloodstream.

The risks are more or less significant depending on the amount of time you spend in a toxic atmosphere and the amount of smoke you inhale. Therefore, physically active people and outdoor workers are more affected by exposure to harmful substances from fires. Those most at risk are the elderly, children, pregnant women, and people with previous or current health problems.

The first symptoms of smog exposure are headache, dizziness, cough, or irritation of the eyes, nose, and throat. In severe cases, asthma, stroke or heart attack are possible.

Because smoke contains a high concentration of various gases, its effects may vary from person to person. Here are details of the harmful effects of the different gases that make up wildfire smoke:

Sulfur dioxide

Colorless, sulfur It consists of and oxygen (SO2). The gas is known for its strong, unpleasant and suffocating odor.

It affects the respiratory and lung systems, causing cough, excessive mucus production, severe asthma, recurrent bronchitis and susceptibility to respiratory infections. SO2 can also cause eye and mucous membrane irritation and serious damage to the skin and eyes. In high concentrations it may aggravate respiratory diseases in sensitive or affected individuals.

The acidity of sulfur dioxide is particularly harmful to the ecosystem. When SO2 is released into the air by the presence of water, it turns into sulfuric acid (H2SO4), which leads to the formation of acid precipitate. Acid deposition damages architectural heritage, acidification of surface waters kills animal species and affects freshwater and marine food chains, and soils are depleted and degraded, causing adverse effects on plants.

nitrogen dioxide

Nitrogen dioxide has an offensive odor and consists of nitrogen and oxygen (NO2). This gas, which is reddish brown in color, is poisonous and suffocating.

NO2 is particularly harmful to people with asthma because it primarily attacks the lungs. Long-term exposure, even at low concentrations, can cause breathing problems with cough or wheezing, which are signs of a possible asthma attack. At high concentrations over a short period of time, inflammation of the respiratory tract is possible.

Nitrogen dioxide, like SO2, contributes to acid rain, which in turn weakens the natural environment and contributes to the formation of tropospheric ozone (a colorless, irritating gas pollutant formed just above the Earth's surface when two pollutants react with sunlight and stagnant air).

Carbon monoxide

Colorless and odorless, carbon monoxide consists of a single carbon atom and a single oxygen atom (CO).

Carbon monoxide is one of the most hazardous gases to health because it displaces oxygen in the air. It directly affects the blood circulation, preventing oxygen from being carried to vital organs such as the heart and brain. A person with low CO exposure may experience symptoms of fatigue, nausea, or headache. High intoxication quickly overwhelms the body, causing impaired judgment, confusion, loss of consciousness, convulsions, chest pain, shortness of breath, low blood pressure, and even coma.

CO contributes to the greenhouse effect: Its oxidation turns it into CO2 (carbon dioxide), which plays an important role in climate change. It also contributes to the increase of CH4 (methane) and N2O (nitrous oxide), which increases global warming and thus damages the ecosystem.

PM2.5 fine particles

The tiny particles emitted from wildfire smoke are a mixture of chemical compounds. They contain Black Carbon, which results from the incomplete combustion of fossil fuels, organic substances that come primarily from volatile organic compounds emitted by human activity and vegetation, inorganic substances such as sea salts, and inorganic species such as nitrate, sulfate or ammonium.

PM2.5 particles (2.5 microns – μm in diameter) released by combustion processes represent the majority of pollutants found in the atmosphere. Their size allows them to quickly penetrate the respiratory system, lungs and bloodstream. They affect the neurological and cardiovascular systems and play an important role in the development of cancer.

How can you protect yourself from smog?

During forest fires, scientists use atmospheric sensors to monitor air quality and inform the public when necessary. It regularly calculates the concentrations of five pollutants (ozone, nitrogen dioxide, sulfur dioxide, carbon monoxide, PM2.5 fine particles).

Air quality is “poor” when the concentration of pollutants exceeds 35 micrograms per m3, with Canada reaching 266μg. When the smog reached New York City, the American metropolis was awarded the most polluted city on June 07, with an air quality index of 80 instead of 50, which sets the limit for a good atmosphere.

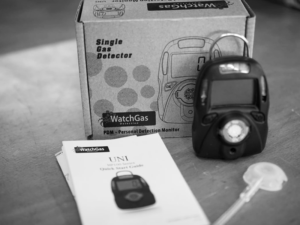

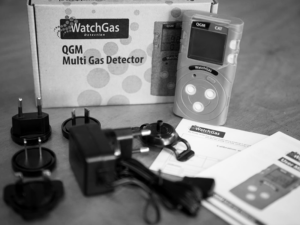

To determine air quality, researchers use portable detectors during their analysis . In this way, they can protect themselves by being warned about gas concentration thresholds and determine whether the atmosphere is breathable.

Following the fires in Canada, the US government urged its citizens to remove masks used during the covid19 outbreak.

Scientists fear the aftermath as impressive amounts of harmful fine particles will remain in the atmosphere without being visible. Authorities want to anticipate this by equipping cities with the necessary equipment to protect the population.

Carbon monoxide is a good indicator of pollution levels. It has a lifespan of several weeks in the atmosphere and can travel thousands of kilometers during this time. Thus, during forest fires, scientists CO emissions Because they are so high, they can track the evolution of a pollution plume over different countries or continents.